Sustainable Environment

Sustainable Environment

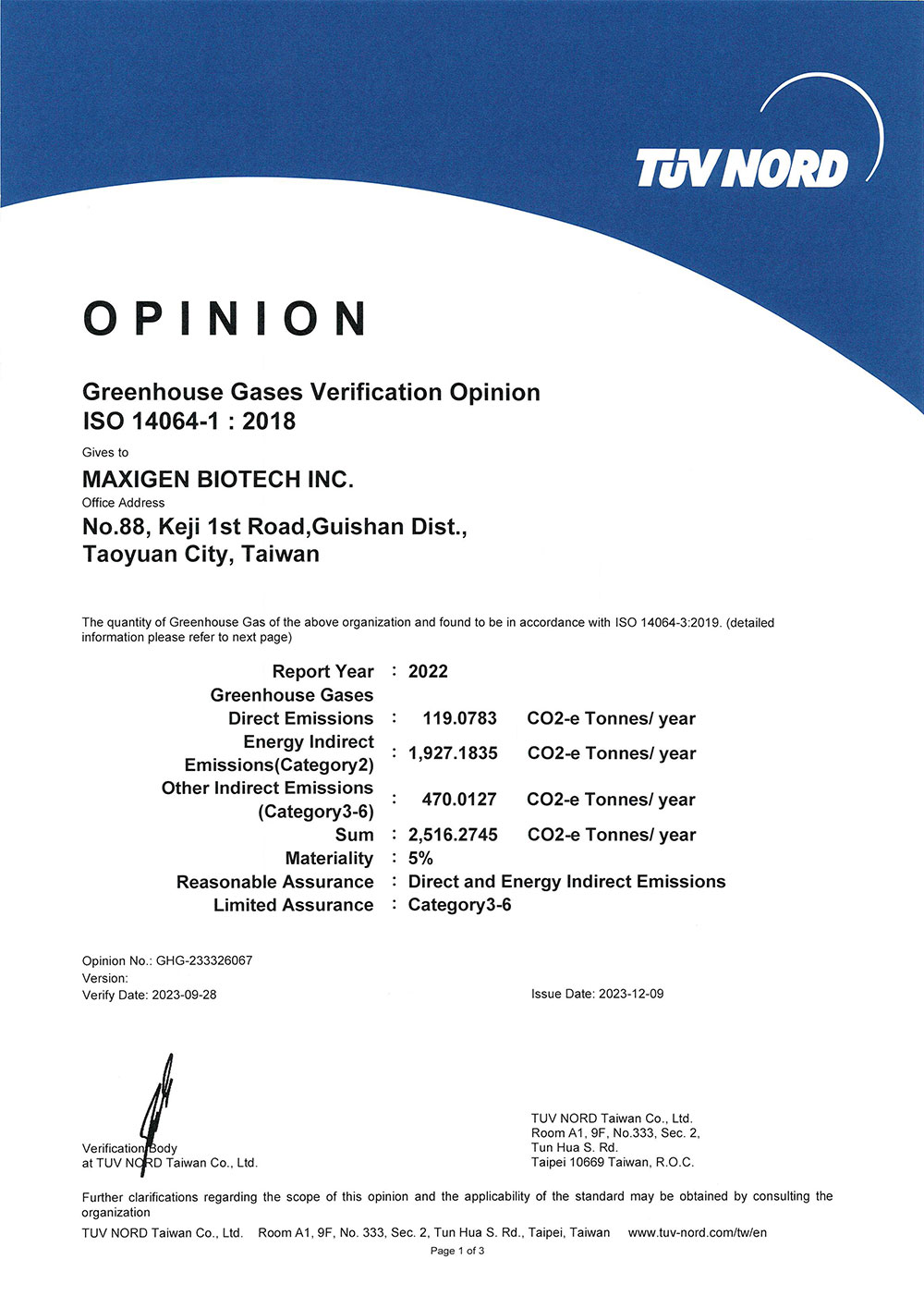

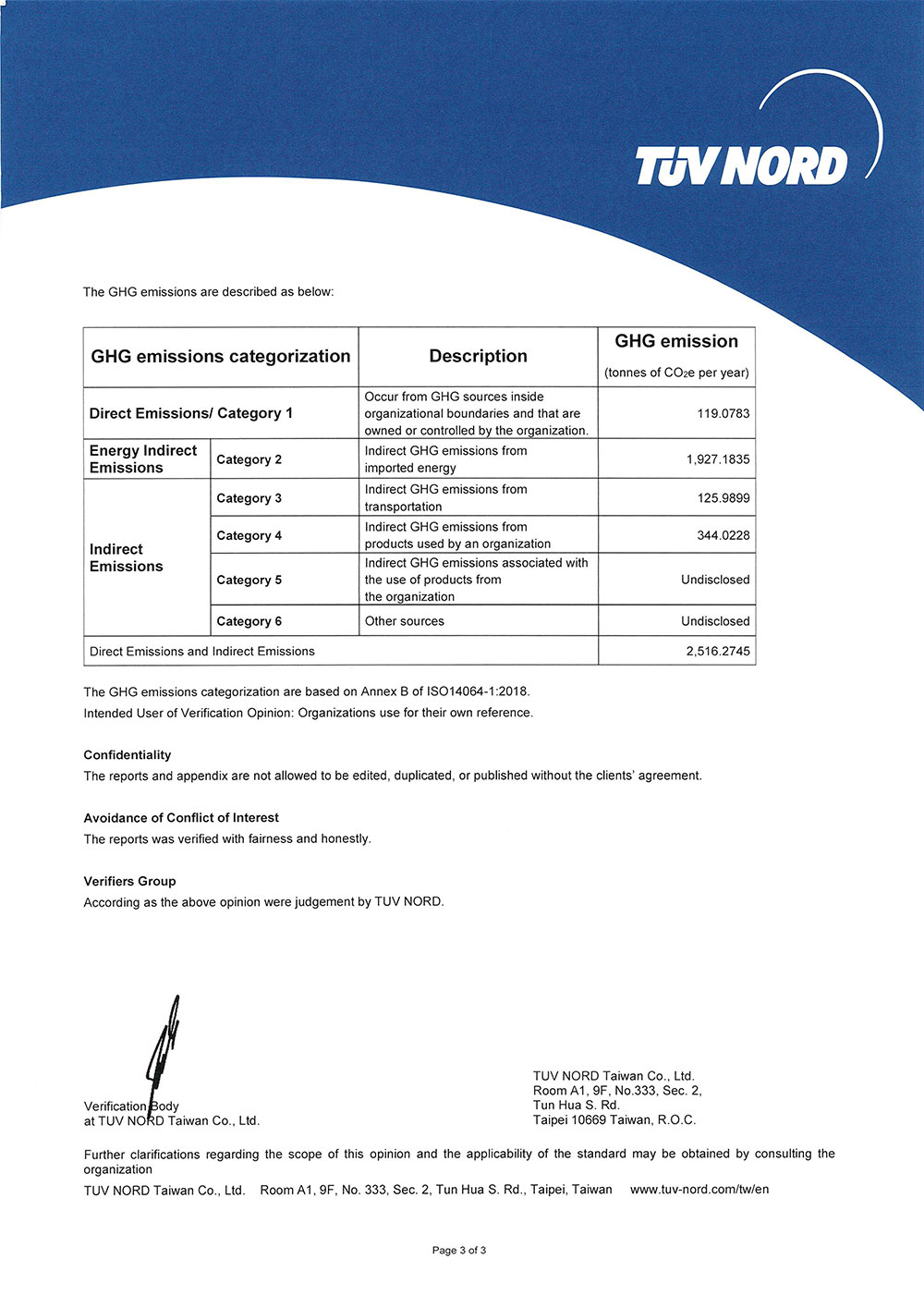

Environmental Management

The Company commits to complying with and continuously striving for environmental, health, and safety improvements. The operation of the environmental management system and the occupational health and safety management system aims to reduce waste and pollution of raw materials during operational processes. As part of MBI’s commitment to environmental sustainability, the Company has conducted autonomous carbon footprint assessments since 2021 and is recognized under ISO 14064-1: 2018. This has been in operation for three years now. In addition to internal audits, an external third-party verification agency, TUV, also conducts annual verifications at the Company. MBI’s latest ISO 14064-1: 2018 certification is valid from October 16, 2022, to October 15, 2025.2018.

Environmental Protection

The Company’s primary greenhouse gas emissions, accounting for 70%, are from purchased electricity, with the remainder being indirect emissions from the use of products (including the purchase of raw materials, packaging, and other goods, as well as waste disposal). Therefore, our greenhouse gas reduction policy focuses primarily on improving energy efficiency, including optimization of chillers, air compressors, and process improvements. Using 2021 as the baseline year, the emission per unit of product in 2022 decreased by 43%, and in 2023, it reduced by 18%.

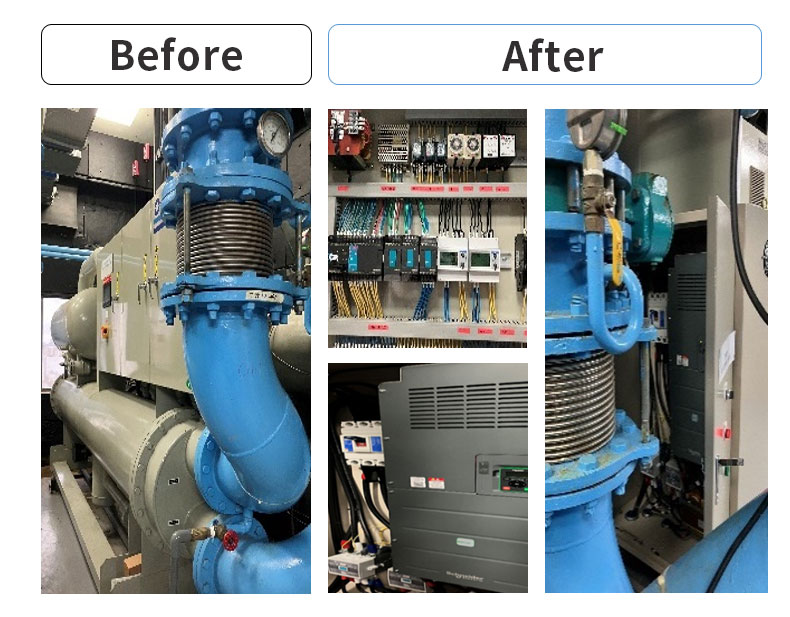

2023 Energy Saving Inverter Improvement Upgrade for Chiller

In 2023, the frequency converter of the chiller underwent an energy-saving upgrade, earning it the 2023 Low Carbon Technology Industry Subsidy and Incentive Program. This upgrade is expected to yield benefits over the next decade, aiming to enhance the operational efficiency of the chiller and improve energy consumption from 0.88 kWh/ton to 0.75 kWh/ton. This upgrade not only enhanced the internal operating environment of the enterprise but also embodied the concept of energy conservation and carbon reduction, contributing to the realization of sustainable development goals and corporate social responsibility.

The energy-saving benefits of this upgrade include an annual reduction of 53.33 metric tons of CO2 equivalent emissions and a saving of 107,734 kWh in electricity consumption. Overall, an energy saving rate of 18% was achieved, which helps reduce environmental impact and saves significant energy costs. Through such technological innovation and sustainable development, the business realizes improved efficiency in its operations and demonstrates its commitment and contribution to environmental protection.

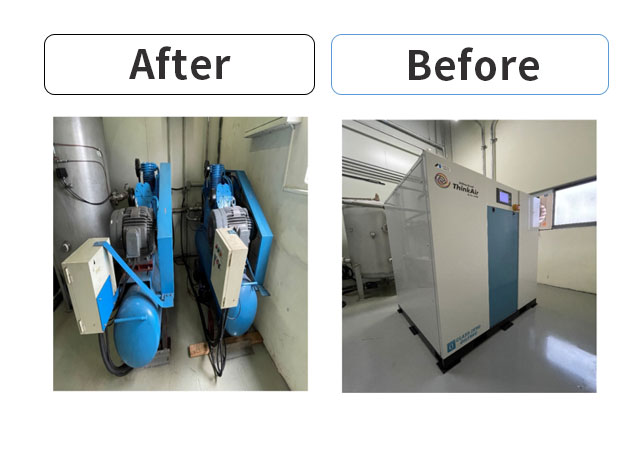

2022 Oil-Free Scroll Air-Cooled Air Compressor

In 2022, the oil-free scroll air-cooled compressor project received the government’s Low Carbon Technology Industry Subsidy. This project involved upgrading the old reciprocating air compressor FTA-150 to the more efficient oil-free scroll air compressor SLPS-220B, which is expected to maintain its effectiveness over the next eight years. This upgrade significantly improved energy efficiency, from 11kW/15HP to 3.7kW/30HP, and also focused on environmental features. The new air compressor operates without vibration and has a reduced noise level from 85 to 59dB, positively impacting the working environment.

In terms of energy conservation and carbon reduction, this improvement results in an annual decrease of 30.487 metric tons of CO2 emissions. It saves 60,731 kWh of electricity, achieving an overall energy-saving rate of 43%. The success of this project not only enhanced the Company’s operational efficiency but also injected new vitality into environmental protection, demonstrating the MBI’s commitment to energy conservation and carbon reduction.